MIT’s Speech to Reality: Robots Build Objects From Your Voice

MIT researchers have built a “speech-to-reality” system that turns a spoken request—“I want a simple stool”—into a functional object assembled by robots in minutes. The team presented the work, Speech to Reality: On-Demand Production using Natural Language, 3D Generative AI, and Discrete Robotic Assembly, at the ACM Symposium on Computational Fabrication (SCF ’25) at MIT, with technical details available on arXiv and a short public demo clip shared on social media [1][2][3][4].

Why it matters: the system lowers barriers for non-experts who lack CAD or robotics skills, moving toward on-demand, prompt-to-production manufacturing where natural language can drive real-world fabrication [1][3][4].

How Speech to Reality Works: From Natural Language to 3D Design

The end-to-end pipeline translates a voice command into an assembled object:

- Automatic speech recognition transcribes the user’s request.

- A large language model interprets intent and generates or refines a 3D design, typically as a mesh from generative AI.

- Because raw meshes are not fabrication-ready, the system converts them into voxelized, modular lattice components.

- Fabrication-aware geometric constraints are applied so the object can be physically built.

- A planning module determines how a robotic arm selects, orients, and interlocks standardized parts on a workbench [1][3][4].

This approach reduces the need for explicit CAD modeling and avoids low-level robot programming—key steps for making natural language to 3D objects viable for non-experts [1][3].

Making AI Designs Buildable: Voxelization, Constraints, and Modular Components

Turning unconstrained AI-generated 3D meshes into buildable structures is a core challenge. The system tackles this by discretizing designs into voxelized, lattice-like modules, then enforcing constraints to ensure stability and assembly feasibility. Standardized parts interlock, enabling reliable robotic assembly and predictable physical behavior [1][3][4].

Beyond enabling automated builds, the modularity supports sustainability and iteration: components can be disassembled, reused, and reconfigured—reducing material waste relative to single-use prints and speeding design cycles [1][4].

Robotic Assembly in Minutes: What the System Can Build Today

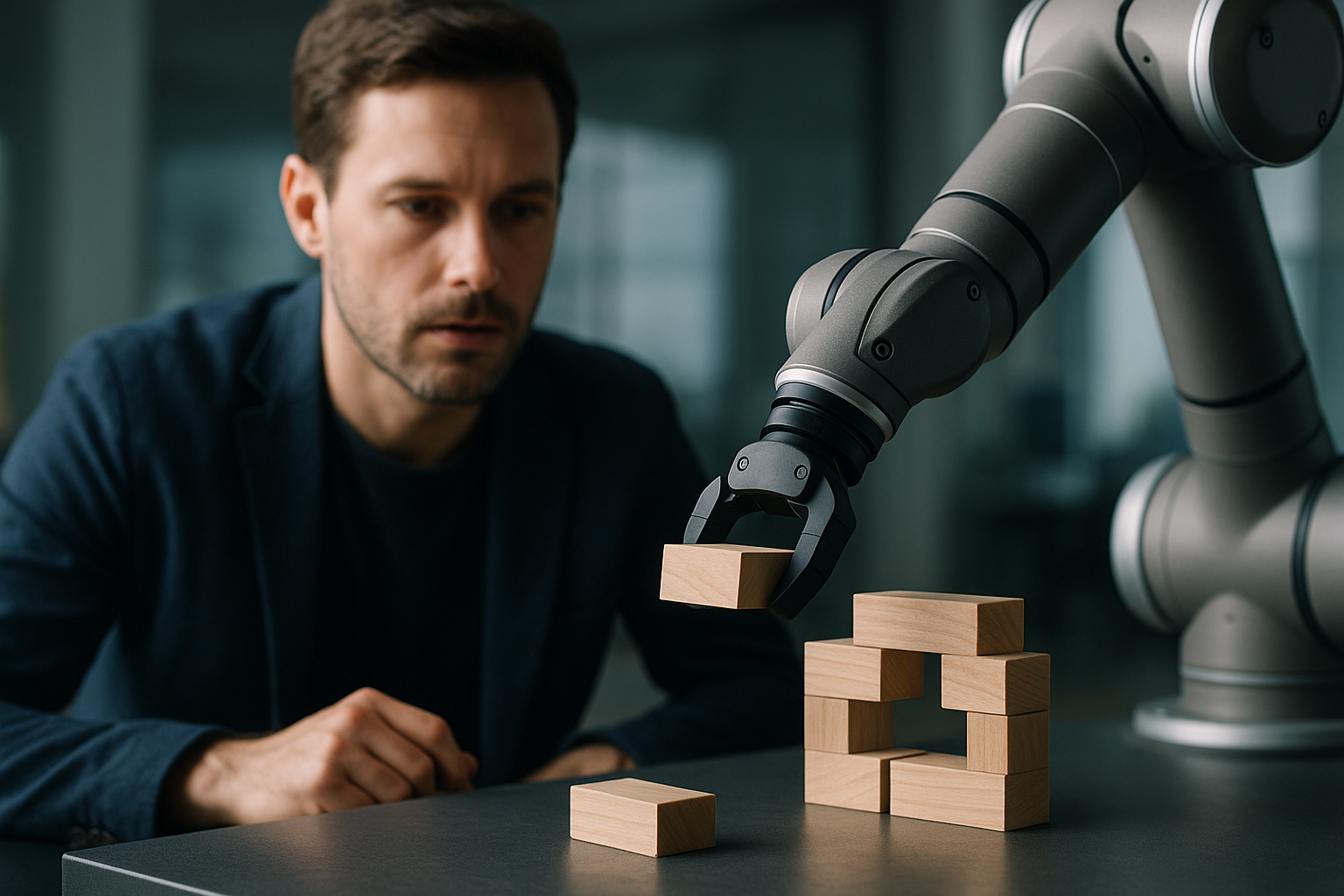

A robotic arm autonomously assembles objects on a tabletop workbench using the planned sequence of part picks, orientations, and interlocks. Demonstrated builds include stools, shelves, chairs, small tables, and decorative items such as a dog statue. Typical production time is on the order of minutes—roughly five minutes in reported cases—substantially faster than many conventional 3D-printing workflows for comparable items [1][3][4].

MIT shared a short demonstration clip publicly, highlighting the speech-to-reality workflow from prompt to completed object [2].

Why This Matters for Businesses: Toward Prompt-to-Production Manufacturing

For operators, product teams, and innovators, the implications are direct:

- Rapid prototyping: Iterate quickly with natural-language prompts instead of labor-intensive CAD updates.

- Mass customization: Tailor form factors or features on demand, without retooling.

- Local/on-demand production: Assemble near customers to shorten lead times.

- Reduced design overhead: Offload early-stage design and planning to AI.

- Reuse and circularity: Disassemble and repurpose standardized modules to cut waste and cost [1][3][4].

This positions speech to reality AI and modular robotic assembly as a potential building block for prompt-to-production manufacturing workflows across furniture, retail displays, and hardware prototyping, especially where fast turnaround and customization matter [1][3][4].

Limitations, Real-World Challenges, and What’s Next

The research highlights remaining gaps before broad deployment. Accessibility beyond controlled lab environments needs improvement, and real-world robustness, safety, and infrastructure requirements remain active challenges. A key technical hurdle is consistently transforming unconstrained, AI-generated 3D meshes into robot-assemblable structures without expert intervention. Even as case studies show strong performance on fabrication feasibility, production time, material reuse, and basic functionality, the team notes accessibility and ease of use outside the lab still need work [1][3][4].

How Operators and Innovators Should Think About AI-Driven Robotic Assembly

If you’re exploring AI in manufacturing and product development:

- Track natural language to 3D objects workflows that reduce CAD and robot-programming dependencies.

- Pilot modular assembly lines focused on a narrow set of standardized parts to validate speed, reuse, and stability benefits.

- Evaluate where rapid, iterative prototyping translates to measurable cycle-time and cost improvements.

- Build governance around AI-to-robot pipelines (prompt logging, safety checks, constraint verification) before scaling [1][3][4].

Key Takeaways

- Voice-to-object is moving from concept to practice via 3D generative AI, modular voxelization, and robotic assembly.

- Minutes-to-make cycles enable fast iteration and potential mass customization.

- Modularity underpins sustainability and reconfigurability—critical for reducing waste.

- Real-world deployment will hinge on accessibility, safety, and robustness beyond lab settings [1][3][4].

Sources

[1] MIT researchers “speak objects into existence” using AI and robotics — https://news.mit.edu/2025/mit-researchers-speak-objects-existence-using-ai-robotics-1205

[2] MIT researchers built a speech-to-reality system that … – Instagram — https://www.instagram.com/p/DR4yC1-E8OU/

[3] Speech to Reality: On-Demand Production using Natural … — https://arxiv.org/abs/2409.18390

[4] Making Physical Objects with Generative AI and Robotic Assembly — https://arxiv.org/html/2504.19131v1